|

|

Stainless Steel Expansion Joint

|

SS Wire Braided Corrugated Flexible Hose

Application

Diluted or concentrated acids, alkalies, liquid ammonia, nitrogen, hydraulica oil, stream air, water, vacuum. Suitable for high pressure and high temperature application.

MAIN APPLICATION |

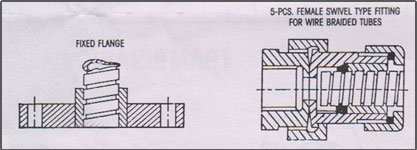

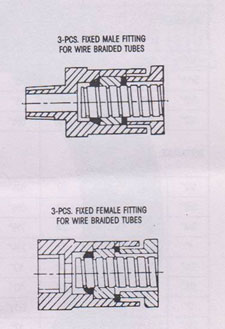

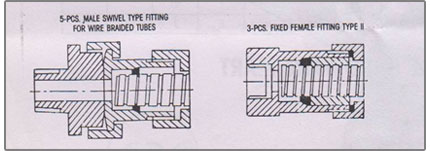

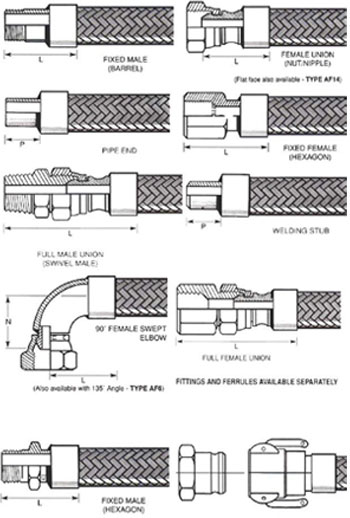

END CONNECTION |

High pressure Tube-wire braided with Copper, Tinned Copper or G.I. Wire for additional pressure and external protection.

Suitable for-carrying Tar, Blast Furnace Gases, Steam, Heavy Hydrocarbons, Gas, Engine Exhaust and Pulverous Products etc. (Stainless Steel tubes for corrosive chemicals and acids). |

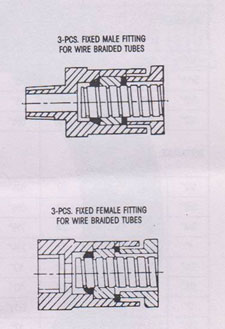

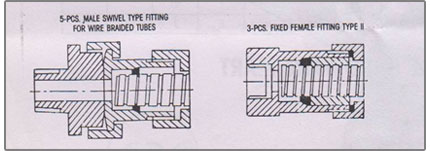

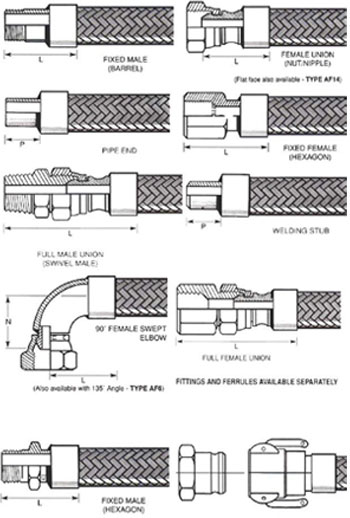

NOTE: The end-connections are fixed with special Compounds. Welding or brazing needs excessive heat which can damage the tube, therefore welding or brazing of end-connections is not recommended. Any other type of end-connections can be manufactured to individual specifications. |

High pressure-More flexibility

Suitable for-carrying Hot water, Lubricating Oil, Steam, Hot Air and Hot Gases etc.

(Stainless Steel tubes for corrosive chemicals and acids). |

|

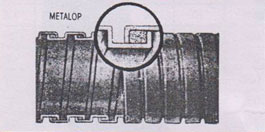

High pressure-Heavy duty

Suitable for-carrying Heavy Hydrocarbons. Tar, Blast Furnace Gases, steam, Engine Exhaust, Gases and Pulverous Products etc.

(Wire braiding upto 50 mm I.D. on request) (Stainless Steel tubes for corrosive chemicals and acids). |

No pressure

Suitable for-carrying Exhaust Gases, Industrial Gases, Hot Air and Incandescent Dusts, Coolant Connections and Drip-proof cable covering for machine tools etc. |

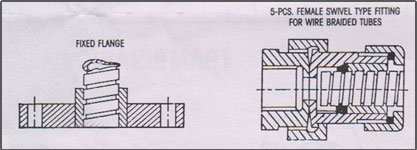

End Connection

TYPE 100 A & 140 A UN-INSULATED

FEATURES :

1. Class 0 fire hazard crassitcation permits installation in return plenum ceilings or other areas where the use of class I air duct would contribute to smoke and name spread in the event of fire.

2. All metal construction permits duct 10 be installed within walls, wall chases or ceilings where inaccessibility necessitates a duct with a life expectancy of the building.

3. Near Zero Permeability and leakage reduces energy loss by delivering dried. moistened, cooled or heated air to the terminal without un- expected transmission loss.

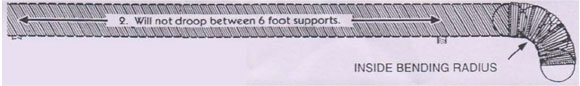

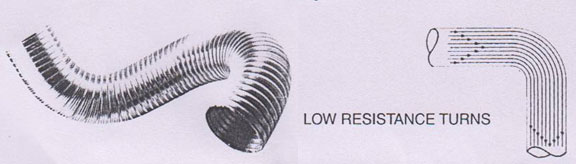

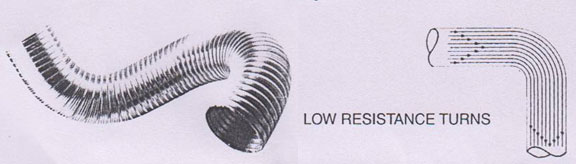

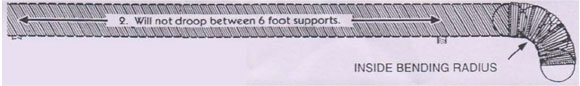

4. Assured attainment of designed air-flow. METAL FLEX will no! droop between six fool supports, and can be installed with severe bends Ihat do not cause bunch-up, ovaling and restriction at every turn. A round ball can be rolled through METAL FLEX turns. Also METAL FLEX is pulled open to the desired length and can be re-compressed where too long providing shortest point to point air flow.

No limitation to installed Length.

TYPE 100 A & 140 A UN-INSULATED

CONSTRUCTION: Type 100A &

140 A special aluminium alloy

prevents corrosion and meta!

fatigue. Close tolerance machine

fabrication produces a continuous

lock-seam that permits duct to be

compressed, pulled open, bent and

rebent without developing leakage. |

|

| PERFORMANCE STANDARDS |

Static Pressure 3" to 10" diameters

12" to 18" diameters |

12" (300mm.) W.C. Positive & Negative |

| 8" (200mm.) W.C. Positive & Negative |

| Maximum Velocity |

5000 f.p.m. \ (25 m/sec.) |

| Temperature Range |

-100°F \ (-73°C to 224°C) |

| Permeance |

Near Zero |

| No limitation to installed length |

|

|

PHYSICAL CHARACTERISTICS

1. Maintains un-restricted diameter in turns.

3. Will not leak, break, delaminate or dry rot when pulled open, bent, re-bent. re-compressed, heat aged or cycled with moist or dried air.

4. Standard I.D. Diameters : 3, 4, 5, 6, 7, 8, 9,10,12,14, 16,18 inches.

5. Standard Lengths : 2.5 meters sections couples to form joint or fits standard round accessories.

BENDING RADIUS (INCHES) |

| DIAMETER |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

| INSIDE |

1.5 |

2 |

2.5 |

3 |

3.5 |

4 |

4.5 |

5 |

6 |

7 |

8 |

9 |

| CENTRE-LINE |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

14 |

16 |

18 |

|